In our modern laboratory we focus on analysis of the properties of the input material as well as the final products with the help of modern testing equipment focusing on mechanical properties, chemical composition and structure of the material in order to satisfy customer requirements on each platform. Furthermore, we work closely with chemical engineers, as well as metallurgical staff in evaluating optimization processes of the heat treatment.

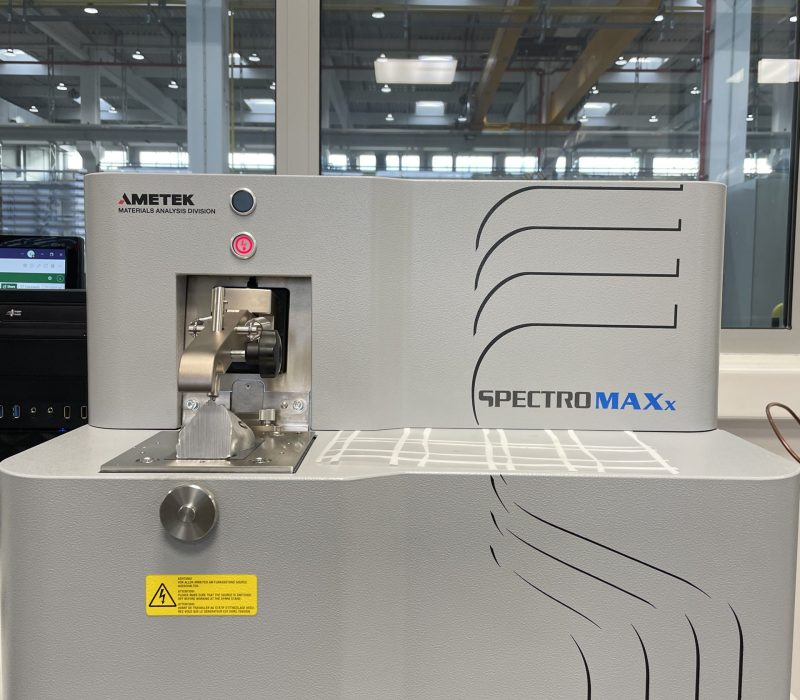

Chemical composition

Chemical composition analysis is performed on a high-resolution optical emission spectrometer. This method is designed to quickly and accurately determine the elemental composition of metallic materials, thanks to which we are able to process a large number of samples in a relatively short time.

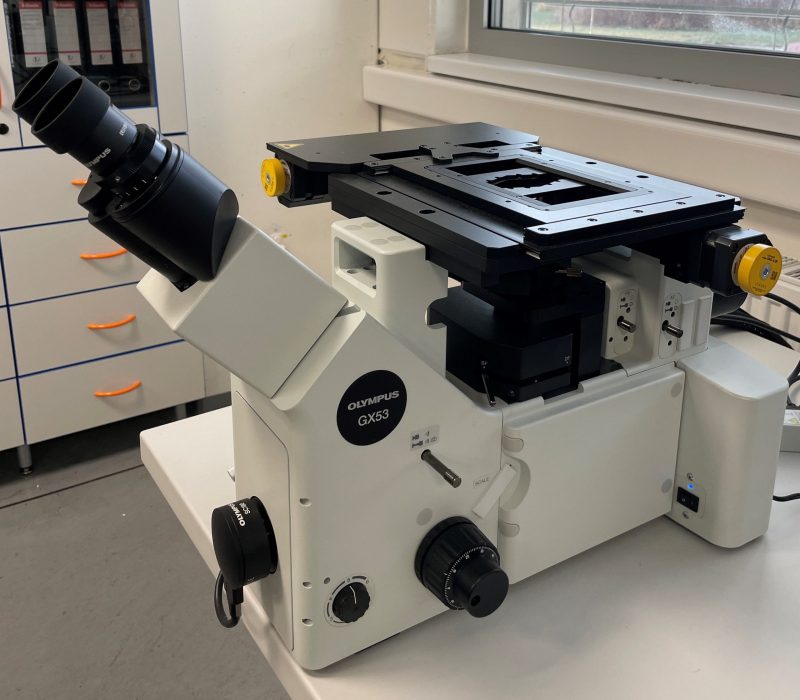

Structure assessment

The assessment of the forging structure takes place in two steps. The macrostructure is assessed using a microscope or stereoscope where the thickness of the recrystallized layer is evaluated. To assess the microstructure we use a modern optical light microscope from Olympus, specially designed for metallography.